The quality of our products is based on continuous improvement, management excellence and customer satisfaction. We test the product during the entire production and development process both in our specialized stations and in external tests, guaranteeing compliance with our rigorous quality standards from the entry of the raw material to the delivery of the final product to the customer.

All our products are subjected to exhaustive quality controls in order to ensure the highest quality:

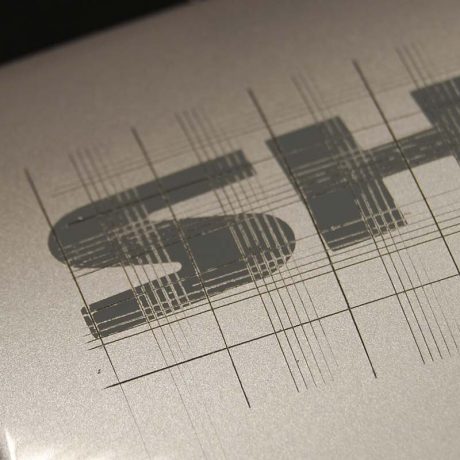

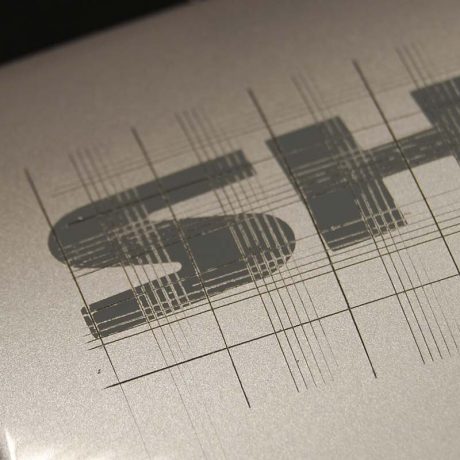

The paint adhesion on SHAD products is evaluated through a specific test, which involves making cuts of different lengths and distances on the area of the paint to be studied. Afterward, an adhesive tape is placed on the treated area and carefully removed to check that the paint does not peel off or get damaged. This procedure ensures that the applied paint meets the necessary quality and adhesion standards to withstand the demands of daily use in adverse conditions.

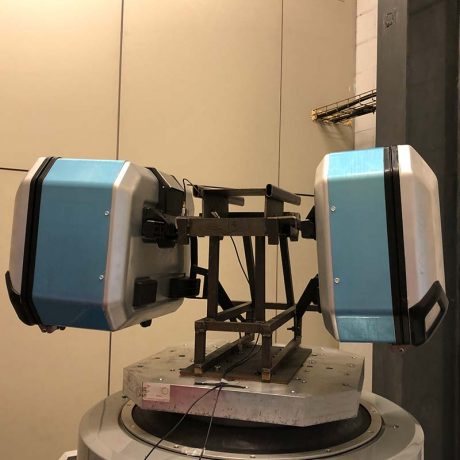

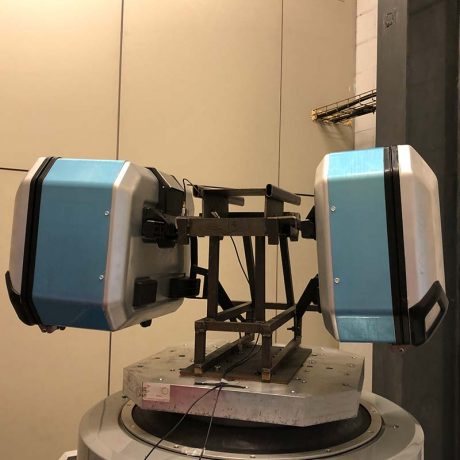

The goal is to replicate the conditions that a motorcycle suitcase is subjected to during riding. Using specific equipment, the vibrations and forces that the suitcase is exposed to during use are simulated. In each test, the suitcase undergoes more than 100 hours of both constant and random vibrations, simulating different road conditions.

This procedure allows for accelerated aging of the suitcase, enabling the evaluation of its resistance to the effects of movement and prolonged vibrations, ensuring its durability and reliability in real-world usage conditions.

During the test, water is applied at different pressures and angles to all points and components of the suitcase, including the locking mechanisms and seals, to ensure that no water leaks through them. The inclination of the suitcase when the motorcycle is on the stand is also considered, as the water’s behavior can vary and accumulate in certain areas in this position. This test guarantees that, even in situations of accumulation, no leakage occurs, providing adequate protection against moisture and ensuring compliance with the IP54K certification.

In this test, the suitcases are exposed to adverse conditions to evaluate their resistance to the effects of the sun, humidity, and temperature changes.

The suitcase undergoes cycles of ultraviolet (UV) light exposure to simulate prolonged sun exposure, as well as to analyze potential discoloration of painted or unpainted parts. It is also verified that the adhesion remains within correct values. Additionally, thermal variation cycles are performed, alternating between heat and cold, to check that the suitcase does not suffer from deformation, contraction, or the appearance of “bubbles” in the painted areas. This process ensures that the products are durable and capable of withstanding the elements without compromising their appearance or functionality.

The tensile test aims to evaluate the resistance of two key elements of the suitcase: the lid in relation to the base, and the base in relation to the motorcycle rack.

Through this test, we determine the maximum load that each SHAD suitcase model can safely support, certifying its stability and strength during riding.

In every production, we conduct impact tests to evaluate the resistance of the suitcase materials to shocks and stresses from daily use. These tests ensure compliance with our internal resistance standards, guaranteeing the durability of our products.

The paint adhesion on SHAD products is evaluated through a specific test, which involves making cuts of different lengths and distances on the area of the paint to be studied. Afterward, an adhesive tape is placed on the treated area and carefully removed to check that the paint does not peel off or get damaged. This procedure ensures that the applied paint meets the necessary quality and adhesion standards to withstand the demands of daily use in adverse conditions.

The goal is to replicate the conditions that a motorcycle suitcase is subjected to during riding. Using specific equipment, the vibrations and forces that the suitcase is exposed to during use are simulated. In each test, the suitcase undergoes more than 100 hours of both constant and random vibrations, simulating different road conditions.

This procedure allows for accelerated aging of the suitcase, enabling the evaluation of its resistance to the effects of movement and prolonged vibrations, ensuring its durability and reliability in real-world usage conditions.

During the test, water is applied at different pressures and angles to all points and components of the suitcase, including the locking mechanisms and seals, to ensure that no water leaks through them. The inclination of the suitcase when the motorcycle is on the stand is also considered, as the water’s behavior can vary and accumulate in certain areas in this position. This test guarantees that, even in situations of accumulation, no leakage occurs, providing adequate protection against moisture and ensuring compliance with the IP54K certification.

In this test, the suitcases are exposed to adverse conditions to evaluate their resistance to the effects of the sun, humidity, and temperature changes.

The suitcase undergoes cycles of ultraviolet (UV) light exposure to simulate prolonged sun exposure, as well as to analyze potential discoloration of painted or unpainted parts. It is also verified that the adhesion remains within correct values. Additionally, thermal variation cycles are performed, alternating between heat and cold, to check that the suitcase does not suffer from deformation, contraction, or the appearance of “bubbles” in the painted areas. This process ensures that the products are durable and capable of withstanding the elements without compromising their appearance or functionality.

The tensile test aims to evaluate the resistance of two key elements of the suitcase: the lid in relation to the base, and the base in relation to the motorcycle rack.

Through this test, we determine the maximum load that each SHAD suitcase model can safely support, certifying its stability and strength during riding.

In every production, we conduct impact tests to evaluate the resistance of the suitcase materials to shocks and stresses from daily use. These tests ensure compliance with our internal resistance standards, guaranteeing the durability of our products.

© NAD, S.L. – ALL RIGHTS RESERVED – LEGAL NOTICE – PRIVACY POLICY – COOKIES POLICY – SOCIAL MEDIA POLICY – ETHICAL CHANNEL– QUALITY, ENVIRONMENTAL& INFORMATION SECURITY POLICIES

© NAD, S.L. – ALL RIGHTS RESERVED – LEGAL NOTICE – PRIVACY POLICY – COOKIES POLICY –– SOCIAL MEDIA POLICY – ETHICAL CHANNEL– QUALITY, ENVIRONMENTAL & INFORMATION SECURITY POLICIES